Grōv Technologies has revealed its latest innovation in controlled environment agriculture (CEA) – the Olympus Tower Farm. Utilising micro-sensors, big data and science-based growing protocols, the Olympus Tower Farm is an automated indoor growing system for commercial scale production of fresh animal feed, aimed at dairy and beef producers seeking more sustainable and economically viable feed solutions.

Grōv’s team of botanists, animal nutritionists and engineers have spent years developing science and technology-based growing protocols for Olympus, which produces unmatched high-density nutrient (HDN) feed, and in trials has shown to provide health benefits for the animals and improved feed-to-yield efficiency. These protocols are formulated by combining thousands of operational and environmental data points from micro-sensors in the tower with daily laboratory analysis of each harvest to ensure the best HDN feed possible.

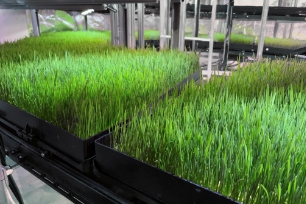

One Olympus Tower takes up only 857ft² of space, and can produce between 5,000 and 6,000 lbs of sprouted wheat/barley grass per day. Each tower uses less than 5% of the water and replaces between 35 to 50 acres compared to traditional farming. Its robotic seed-to-harvest technology means that the Olympus requires minimal labour input. Plant growth is constantly analysed with data collected from integrated tower sensors and testing performed by Grōv’s scientists to adjust and optimise tower performance, yield and nutrition.

Grōv Technologies is entering the US$90 billion global dairy and beef cattle feed market at a time when the industry is at an inflection point. Indoor vertical farming technology has emerged as a viable solution to help farmers address the challenges of rising feed and labour costs, supply-chain disruptions, water shortages and green-house-gas emissions.

Dairy farm collaboration

As part of its pilot program, Grōv partnered with Utah’s largest dairy operation, Bateman Mosida Farms, to build the world’s first commercial-scale CEA feed centre, based on its Olympus Tower system. Initial results have proven encouraging. Controlled studies of more than 600 animals, which began in 2019 on the Bateman dairy, found that cows fed a ration including Grōv’s HDN sprouted wheatgrass more efficiently produced milk on less feed, thus improving the farm’s bottom line. Additionally, these independent trials showed that Grōv’s feed product also improved meat quality in beef cattle.

Due to the success of the collaboration, Bateman has committed to feed up to 5,000 animals in 2021 using the Grōv feed system.

“The results we’ve seen using the feed from Olympus are exciting,” confirmed Brad Bateman, owner/partner of Bateman Mosida Farms. “It’s evident that including Grōv HDN in the cow’s diet improves feed production efficiency. We pride ourselves on our commitment to sustainability and ensuring the best product possible for our customers. Olympus has put us on the path to more efficiently feed our animals year-round and ensure the next generation of Batemans have a sustainable and profitable future.”

“Increased consumer demand for traceable, local food and the agricultural risks associated with climate change have made it essential for farmers to adopt sustainable technologies,” added Steve Lindsley, president of Grōv Technologies. “We believe Olympus holds the promise to help operators meet the challenges they face today. Implementing Grōv technology and science has proven to grow a more nutritious feed and sustainably produced foods, while improving long-term economic viability for farmers.”