iFarm (Intellectual Farms Oy) is a Helsinki-based international company that develops solutions, platforms, and technologies for indoor farming and agribusiness. Recently iFarm’s engineers began designing a custom vertical farm that could flourish inside the body of a commercial aeroplane, with the potential to extend the life of decommissioned aircraft.

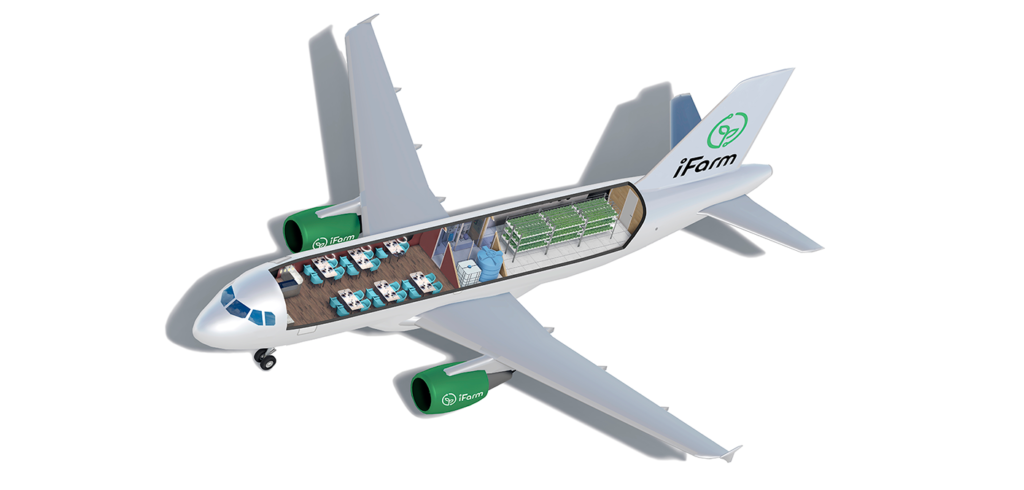

Experts from iFarm were approached by a European airline with the brief. In response they proposed converting a passenger plane’s cabin into a salad bar and designed a vertical farm with a total growing area of 135 m² in the aft section of the aircraft so that the bar can offer 14 kg of fresh salad daily.

For iFarm, the project demonstrates another innovative way of integrating agrotechnology into seemingly unsuitable infrastructure and the versatility of vertical farming.

While contemplating additional ways of using the wide-body aircraft to grow plants, engineers suggested a number of configurations that make such refitting not only useful for advertising purposes but also commercially viable. For example, a farm located in the body of a decommissioned cargo jumbo jet can produce up to 1.5 tons of greens per month.

“Vertical farms are good because they can be installed in a wide variety of spaces, from abandoned subway stations to airplanes that no longer serve their intended purpose. We will be happy to cooperate with companies that think outside the box and consider such high-tech repurposing options. This project does not yet have a deadline, but it has already drawn the attention of specialized design bureaus as an easily scalable example of old aircraft upcycling.” commented Kirill Zelensky, CEO of iFarm Europe.

Not all obsolete aircraft are recycled. The airline industry has long used conservation methods to repurpose aircraft, such as, sending airliners to spare airfields in dry climates, where they essentially serve as containers of spare parts. Each aircraft includes about 350,000 individual components, and many of these planes remain useful long after their last flight.

But some owners prefer upcycling to disposal in an attempt to provide “second life” old aircraft, especially those with some historical value (e.g., the first airplane of the airline). There are existing examples of creative airliner usage, including dozens of on-board cottages, offices, cafes, and hotels all over the world, and even an old soviet Yak in Georgia that hosts a kindergarten.

For airline companies, the opportunity to upcycle planes into highly sustainable vertical farms is an enticing one. When an industry known for its high carbon footprint can find new ways to support sustainable practices, it could offset emissions, enhance a brand’s image and have a genuine impact on the environment.