In 2020, Indiana-based Vertical Acres signed a deal to acquire seventeen cultivators, three propagators, and one fertigator from Canada’s CubicFarm Systems Corp, at a cost of C$3.8M / US$2.9m. Two and a half years (and one pandemic) later, that automated, controlled-environment growing technology is now fully commissioned at Vertical Acres.

CubicFarms’ patented technology will enable Vertical Acres to grow and distribute commercial quantities of fresh produce for their region. Vertical Acres will initially focus on growing and harvesting a variety of lettuce and microgreen crops, with each module capable of growing over 100,000 heads of lettuce and 12,500 pounds of microgreens every year.

“Staple crop production has a proud tradition in our region, but our family sees the need and potential to offer additional crops year-round to our local community. Particularly in today’s times, it is crucial to seek solutions that minimise water, land, and pesticides for growing greens, and our CubicFarms system reduces our reliance on all three,” said Vertical Acres’ owner Fred Schakel. “We are thrilled about the prospect of supplying fresh, nutritious greens every day throughout the year, independent of the wide range of weather conditions we experience here in Indiana. The use of technology and automation will also allow future generations in our family to farm more efficiently.”

CubicFarms CEO, John de Jonge, stated: “We are delighted to bring this project to fruition for Vertical Acres, enabling them to successfully cultivate high-quality, locally grown produce in Indiana and the surrounding regions. Fred Schakel and his family will enable freshly picked, locally grown lettuce and nutrient packed microgreens to his surrounding areas even when snow is falling in January. Our patented technology empowers them to maximize production efficiency per cubic foot while significantly reducing the physical footprint compared to traditional farming operations.”

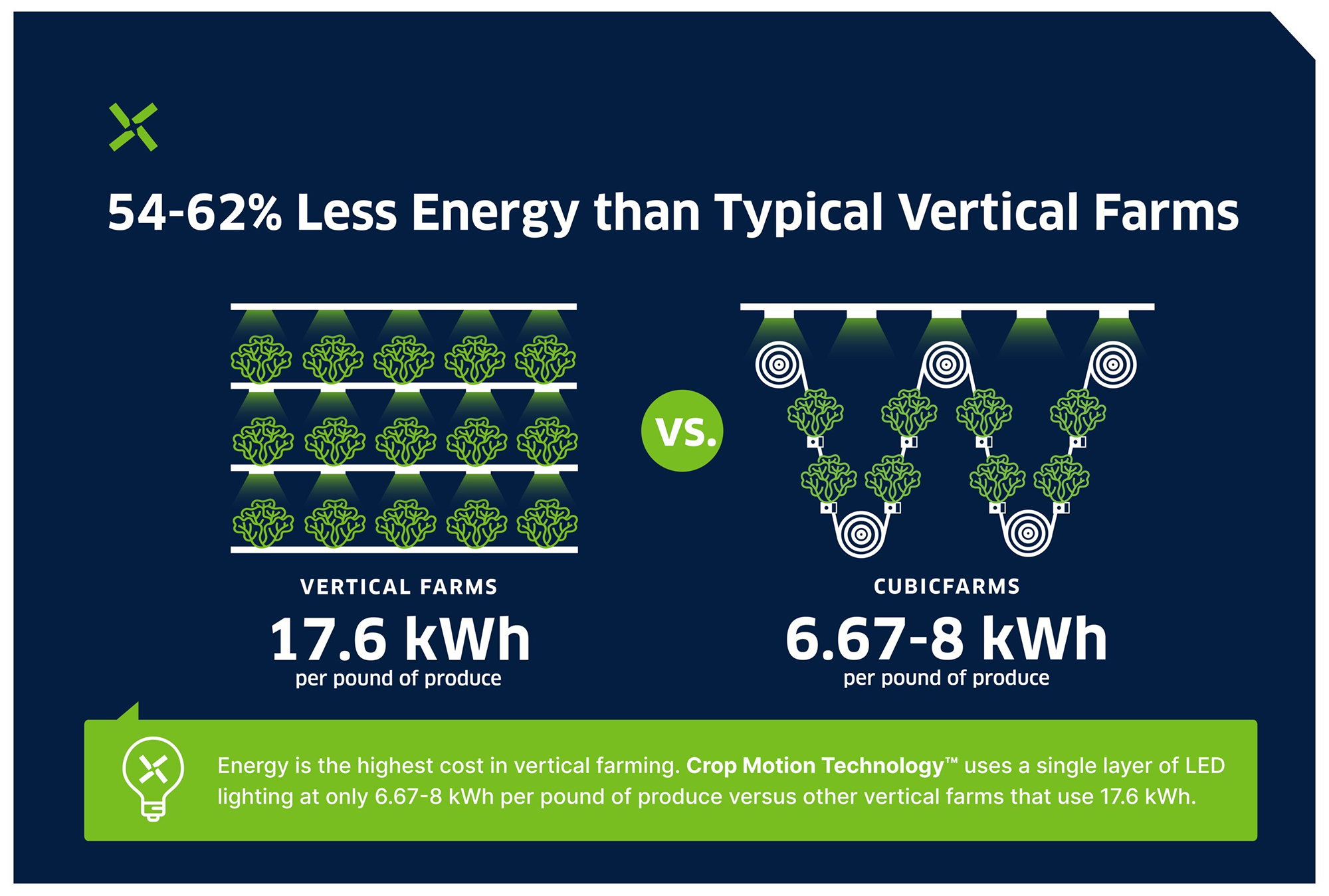

Patented Crop Motion Technology saves energy

CubicFarms’ patented Crop Motion Technology™ moves plants to one layer of LED grow lights, unlike typical rack and stack layouts of other vertical farms that use multiple layers of energy-intensive LEDs. This results in energy savings of over 50% per pound of produce vs other vertical farms.